-

Home

-

About

-

Products

-

R&D

-

Development

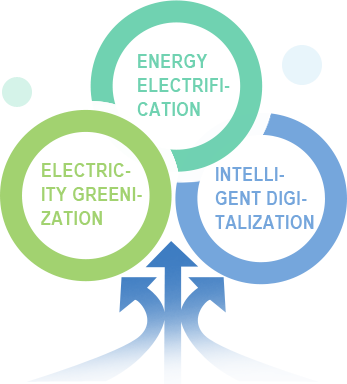

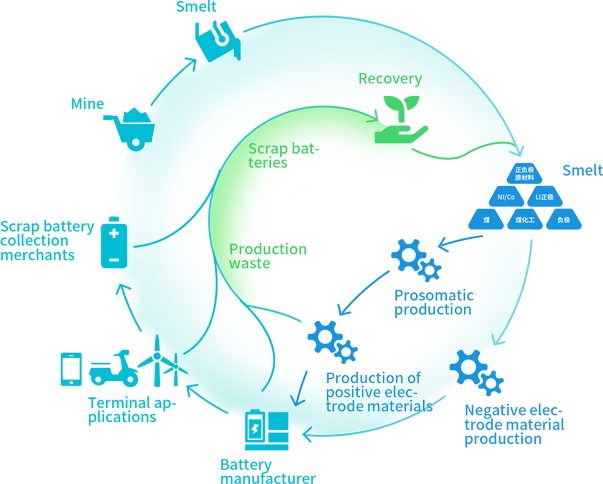

Sustainable development

Improve energy production efficiency, reduce energy costs,and increase sustainability of energy resources.

Innovate the technology of the new energy industry, and develop from the traditional energy production and utilization mode to a more efficient and cleaner direction.

-

Investment

- Contacts

Home

Home Legal Notice

Legal Notice

Enterprise Profile

Enterprise Profile